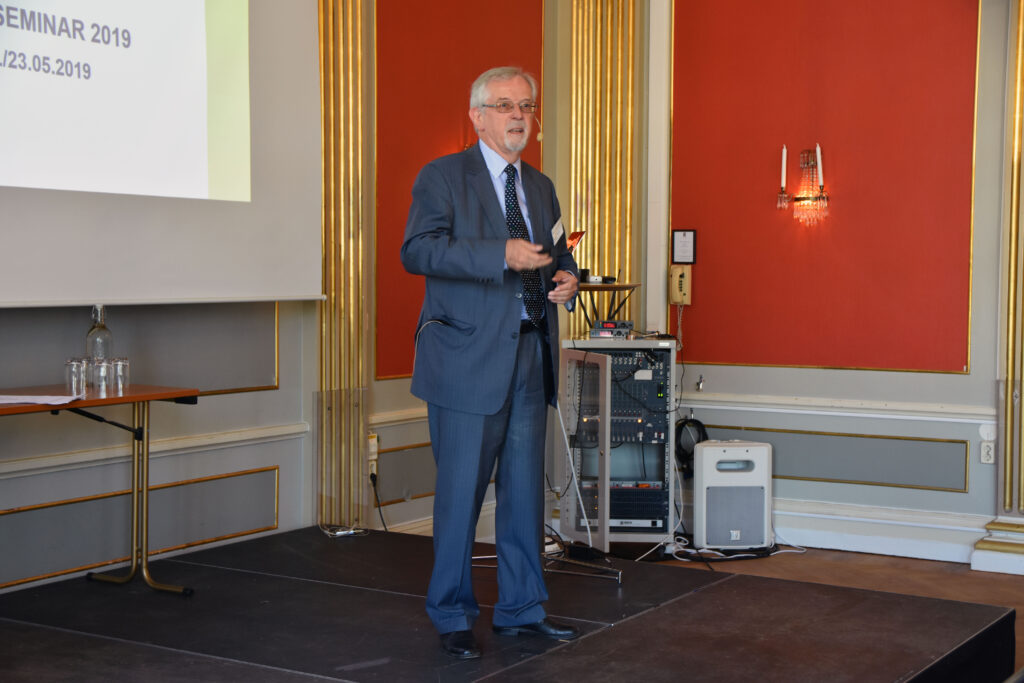

Prof. Dr.-Ing. Gerhard Wagner, Ruhr-Universität in

Bochum, Germany and Hannu Rantala, Senior Chief Engineer, Konecranes Finland

Lifting Devices in Nuclear Facilities:

Design of Cranes, from Standard to Practice

Mankind consists of two major fractions, theoreticians and practicians on either end of the scale and thousand shades of grey between the extremes. High technology applications demand creative co-operation between the two types of skills. At NCS 2019 in Växjö the audience had the pleasure to listen to two well renowned experts on standards, Prof. Dr.-Ing. Gerhard Wagner, and Hannu Rantala, Senior Chief Engineer. After the summary there is a short interview and discussion on the topic of crane design from standard to practice and the future of European engineering.

Philosophy of EN 13001-series

Gerhard Wagner, professor of Ruhr-Universität in Bochum, Germany, has a very profound background in both theoretical and practical aspects of mechanical engineering and crane safety. After an industrial career he joined the academic world again and finally reached the position as president of the university. He has also been deeply engaged in international standardization, a.o. as chairman of the technical committee ISO/TC 96/SC10 (Cranes – Design General) and as convenor of CEN/TC147/WG2. He truly possesses a thorough knowledge about the background of EN standards.

Therefore Prof. Dr.-Ing. Wagner is one of the leading experts in his field and able to transfer valuable know-how to all of us, who want to know more about how standards may help us to design and use cranes with an optimum of safety.

“The aim of EN 13001 is to create generic standards for all crane types and to overbridge the gap between health and safety requirements and design features of all technical details of the crane. The EN 13001 standards have a consistent design and a uniform format, including static and dynamic factors, as well as details of steel structures, hydraulic cylinders, chains, couplings and gearboxes etc.”

Limit states versus allowable stress method

When it comes to calculation of allowed loads EN 13001-1 contains two options. The allowable stress method is restricted to linear stress relations and to unfavourable mass distribution. In all other cases the limit state method should be used.

“Loads should also be combined in order to determine both dynamic and static effects and stress influence on the crane structure. There are favourable and unfavourable masses and load combinations, which all can be evaluated using the EN 13001.”

“Among other factors I would like to mention the total number of working cycles, the average distances, the load spectra and the average number and intensity of accelerations per movement. The difference is the number of load cycles and the speeds of the crane movements. In the M-class the parameters are different, which may lead to erroneous applications. For example, travel speed or operation time are not relevant for determining fatigue influence on a wheel shaft.

The design should be based on maximal values of the parameters within the specified classes.”

Prof. Dr.-Ing. Wagner concluded his review of the present situation by evaluating some features of the EN 13001 standard.

“EN 13001-1 will determine the classification of the cranes. All loads and load combinations are according to EN 13001-2, the static and dynamic proofs for steel structures are according to EN 13001-3-1.

For ropes it is important that fatigue proof according to EN 13001-3-2 should be based on rope bends instead of operation hours. Minimum breaking force Fu is used as a base value and discard criteria will follow ISO 4309. The results should be close to DIN 15020. However, the ISO/TC96 committee considers using FRd, the force and respective number of bends to define the limit design force for fatigue.”

Regarding the connections between ISO and CEN standards, there is an ongoing discussion for a revision of ISO 16625, Cranes and hoists, for the section “Selection of ropes” with the objective to connect the proof of competence to the number of load cycles. The respective clauses in EN 13001-3-2 might then be aligned with ISO 16625.

Recent Development in EN Standards

Hannu Rantala, Senior Chief Engineer at Finnish Konecranes, has a long list of merits in the field of international standardization, including being Convenor of CEN/TC147/WG3 and WG14 and membership of several ISO/TC96 and CEN/TC147 working groups. He also knows the everyday challenges of crane design and manufacture.

“Remember, standards are not text books but technical regulations at conceptual level. They do not specify any particular technical solutions as long as the function and SAFETY requirements are fulfilled. As such they also have to reflect the contemporary technical level, “state-of-the-art”. At present a number of revisions in crane related standards are coming up, for example clarification of application of the 125% overload test in the EN 15011 (Bridge and gantry cranes) and EN 14492-2 (Power driven winches and hoists). In addition, many amendments are added to other EN standards.”

It is interesting to note that crane runways, which are permanently fixed to the building, will fall under another standards and directive than the crane, i.e. Construction Product Regulations. Light crane systems standard EN 16851 gives some new views in this respect.

Classification and standards

In EN 15011 classification is based on EN 13001-1. The user will get full benefit of the system when, instead of jumping into stating the classes, but splitting the intended use into work tasks with specific loads and annual numbers of work cycles. This is also most useful in nuclear applications, where the crane working processes are typically well specified.

“The crane class is not a quality class; the specification is made according to the intended use. Note that classification is not mandatory. It does not presume a certain crane life span in years but in work cycles. Neither is it a provision for a high-risk application, where risk coefficients of EN 13001-2 shall be applied.”

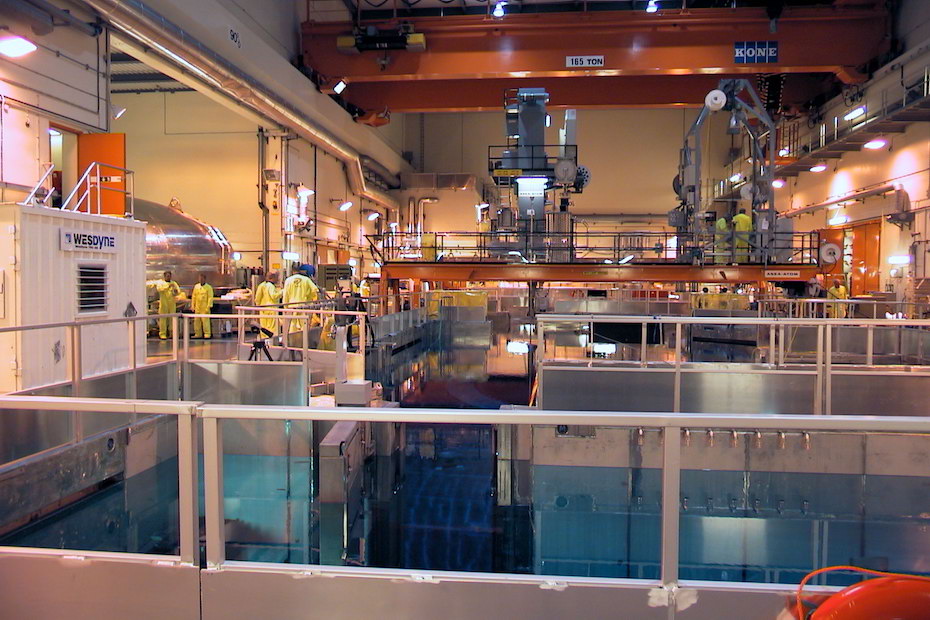

If we have a look at EN 13135, Requirement for equipment, it covers many important components of a crane system: backup brakes, rope systems, gearboxes etc. There are two special applications, high-risk handling of hot, molten metals and radioactive materials and design calculation rules concerning motors.

“Rope systems are in a key position. The single failureproof rope system (SFP) sets a number of more severe requirements on risk factors compared to EN 13001-3-2, such as rope terminations, type of rope – in nuclear power plants steel ropes should be damage tolerant.”

There is another interesting subject – are cranes in nuclear applications within the scope of the Machinery Directive or not?

“In the Machinery Directive (MD) 2006/42 we find the passage ‘cranes, which do not give rise to a risk of emission of radioactivity and/or failure of which do not directly generate radioactive emission, are not excluded from the scope of the Machinery Directive.’ This means that radiation critical cranes obviously are not included in the MD. Therefore, special, overriding national requirements may be set on these cranes, while the MD and EN standards should be applied on conventional cranes in the nuclear plant. The first category requires high standards regarding materials, functions, safety equipment, inspections and maintenance. Of course, EN standards and MD concepts can be applied on the radiation critical cranes in addition to national rules.”

Two Wise Men Talking about Safety and Standards

After the first day of the KIKA seminar Prof. Dr.-Ing. Wagner and Senior Chief Designer Rantala met for a professional chat about the situation regarding the EN standards and other regulations concerning cranes in a nuclear environment.

“EN 13001 is a complex document, which takes at least two days to read. The standard highlights design based on cycles, not on operational time. It is sometimes very difficult to change the minds – why should one do it as everything has gone well with the existing standards. One example – it took us ten years to convince US authorities about the ISO M-classes. My intention was to inform you that you have to design according to the Machinery Directive. Introduction of DIN 15018 lead to a lot of resistance in Germany when it replaced DIN 120”, says Prof. Dr.-Ing. Wagner.

“Time based design criteria are always connected to the M classification. For those, who study it now it feels like nonsense, but in the sixties, it was a useful principle. Earlier only two classes of operation existed in mechanical design. Now the load cycles determine the design”, Rantala comments.

“Actually, the rated capacity is the load limiter. I hope Hannu and I managed to present the same safety issues to the audience. One example is the safety of wire ropes. The margin should be higher, one has to calculate the rope force safety factor as two times all partial loads. Another example – in our old office we had a catalogue of approved hooks – the new standard allows you to use any hook that fulfils the requirements.”

What about the special requirements for cranes in nuclear power plants?

“You have a lot of cranes, which are not operating in a radioactive environment and which fall under the scope of the Machinery Directive and ordinary standards. But for the cranes outside this field, its should be of a mutual European interest to have a common standard or regulation covering the exceptions.”

A thing that worries both Prof. Dr.-Ing. Wagner and Rantala is that many European companies are reducing their engineering activities.

“They should focus on pre-engineering and not hand over everything to China and India. Some decades ago, most European technology companies employed a lot of engineers – now there are only salesmen and lawyers. Politicians are not interested in standards and if we neglect our technological competence we are on weak ice. Good control systems for cranes can decrease the risks of overloads and damages. We need intelligent cranes, computer controlled, more sophisticated cranes. Remote maintenance is growing, there is a demand for good, highly qualified engineers in Europe.”