Norbert Schilling, head of Project Engineering, NKM Noell Special Cranes GmbH, Germany

Norbert Schilling, born in 1962, graduated from the University of Braunschweig, Germany, with his main subject Crane Design. Later he worked as a researcher at the university before joining NKM Noell in 1994, now a part of the French Reel Group. Norbert has long experience of special cranes, e.g. for steel works and aluminium smelting plants and harbour cranes – for example in Gothenburg, Sweden. Norbert Schilling is a member of a committee that develops new standards for lifting equipment in nuclear power plants under the supervision of German KTA (Nuclear Safety Standards Commission).

Q: It seems that KTA is becoming more and more accepted outside Germany as a general standard for lifting devices in the nuclear industry. What is your explanation for this trend?

NS: KTA is not unique, in most other national regulations and standards we find the same aspects, but in Germany we are very fundamental in our definitions and requirements. The KTA standards are very close to DIN standards, which are commonly used in manufacturing cranes and similar lifting equipment. We look at harmonized European standards when revising the KTA standards. In 2006 a number of German standards were no longer valid and they are now replaced by corresponding EU standards.

Q: How will KTA keep up with the latest technical development in the nuclear crane sector?

NS: Many KTA standards were completed in 1999, which means that the whole digital control revolution and the introduction of frequency drives are missing in the texts. Our focus is now to reflect the development at least at a European level and to incorporate valid EU standards regarding calculation requirements. At present, in 2008, no complete calculation standard concerning mechanical parts for nuclear cranes is available.

Q: What will happen cross-border, are you going to make KTA an international standard in respect to the acceptance KTA has met, at least in the Nordic countries?

NS: The revision of KTA, hopefully to be completed in 2010, will however stick to German DIN standards, but we hope to bring into the revised standards the ideas of the most stringent procedures of calculation and risk analysis. Many national standards are based on DIN designs. We hope that in the next step other countries will follow us and we will establish a basis which will be understood by everybody.

Q: German NKM Noell seems to have an advantage as other countries apply KTA standards. How will you benefit the situation?

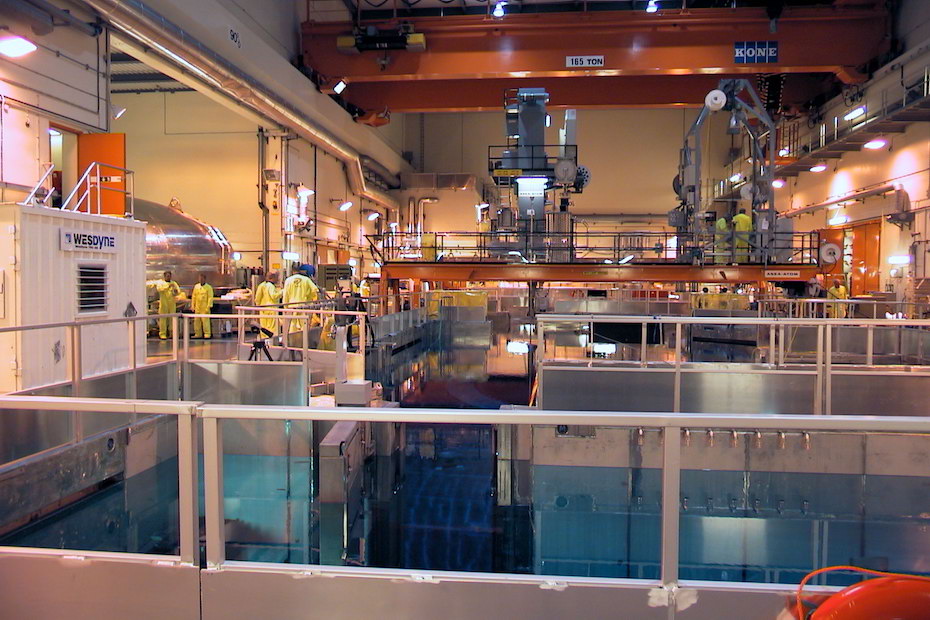

NS: It is true that KTA has been used in Sweden at Ringhals and the standards will be used in Olkiluoto in Finland for the new cranes from Eiffel, France. It is interesting that KTA turned out to be the solution in comparison with French EDF standards. Even in the new French EPR project Flamanville, to be completed in 2012, a new hoist is based on KTA. The reason, as I see it, is that KTA is based on a real standard, which covers all phases from design to inspection. Therefore KTA is at least equivalent to EDF for small hoists. NKM Noell has positive expectations for the future, for example when talking about retrofits in Switzerland. We are not too far away from our international colleagues and competitors – same requirements, same thinking, but different formulas. Maybe an international version of KTA would be the right way to go as the standard is easily adaptable.