Bradford P. Lytle P.E., NASA Kennedy Space Center and past Chairman of ASME Committee on Cranes for Nuclear Facilities

One of the most honoured guests in Växjö was Bradford P. Lytle from the NASA Kennedy Space Center in Florida, USA. He has a profound experience of one of the most demanding operational environments for lifting equipment, the space centre, where every mistake or failure could cost a billion dollars.

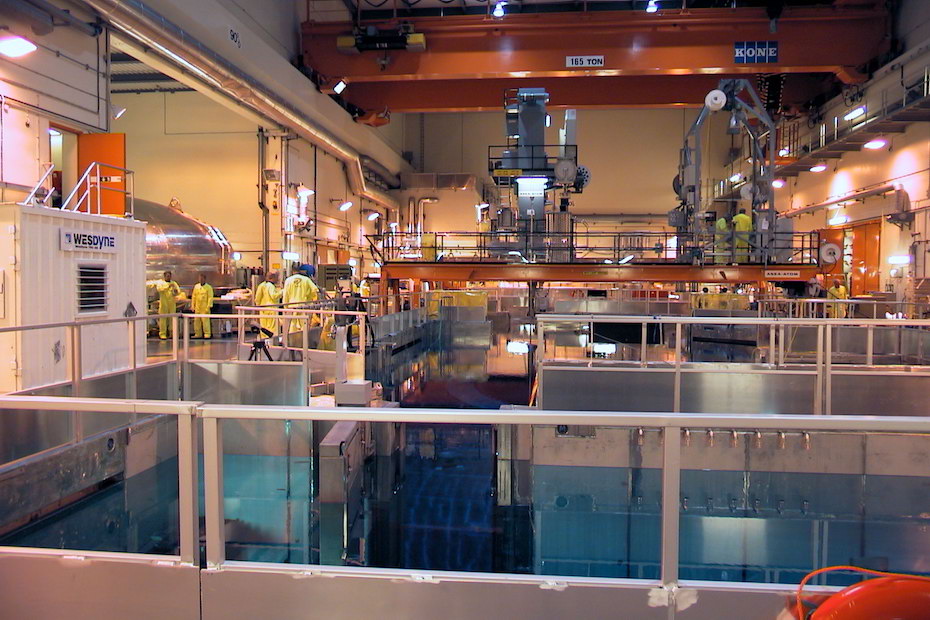

“It is interesting to be back in Europe and for the first time ever in Scandinavia. I toured Europe in my youth and I have many good memories from the trip. I met Kjell Andersson, the secretary of KIKA, at an excellent lifting device seminar in Las Vegas three years ago. I try to meet as many people in this industry as possible – crane specialists in aerospace are a very small crowd and our technology actually originates in the nuclear industry. I have been a member of the ASME committee for nuclear cranes for many years, which has influenced my career path. The committee work has also given me insight in the industry and allows me to draw conclusions from the experience of my colleagues in the nuclear industry.”

But, anyway, Kjell Andersson managed to tempt Bradford to come to Växjö and the KIKA seminar to tell more about how to make safe cranes even safer than they already are.

“I have been involved in investigating crane accidents and in my opinion the reason behind many incidents is that people don’t understand the basic elements of lifting. We are truly not talking about rocket science, but good engineering. Human mistakes may be avoided only by clever technical solutions and intelligent inspection – don’t mess things up!”

Bradford meets with the ASME committee three times a year. He communicates with manufacturers, utilities and operators.

“I have a thorough interest in ultra-safe material handling. At NASA the stakes are huge in our daily operations and we have to make every effort that nothing ever goes wrong. Here in Växjö I hope that I have made people think about things outside the ordinary box, to have given them a different point of view. I have seen that all across the world we have similar engineering issues, some examples of different approaches, but we make almost identical corrections. I feel we are on the right track. In the USA we are in a very intense stage of preparing operation and maintenance documents, because not very many good ones are available at present. All inspections should be very rigorous and creative – failures can be prevented if you are able to imagine all possible risks.”